LDSF Large Diameter Split Frames

DynaPrep LDSF Large Diameter Split Frame Clamshell Pipe Cutters/Bevelers

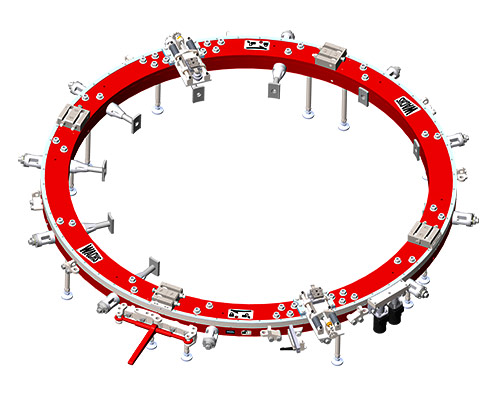

E. H. Wachs LDSF Large Diameter Split Frame with hydraulic drive is designed for cold cutting, beveling, facing and counterboring on large diameter pipes, vessels and flanges. It’s been engineered to incorporate multiple advancements designed to make it stronger and faster to set up and operate. Picking up where the MDSF split frames leave off, four standard LDSF Large Diameter Split Frame sizes will cover a range from 60in-120in O.D. (DN1500-DN3000). Each machine covers a 15in (381mm) diameter range and will simultaneously cut and bevel most wall thicknesses and materials.

The internal, full bearing construction contributes to the LDSF Large Diameter Split Frame’s smooth operation and long service life. Spring loaded O.D. (outside diameter) tracking slides for irregularly shaped or out-of-round pipe and vessels are standard, and allow the tooling to maintain continuous contact, producing precision weld preps with consistent lands. A new CRBM Counterboring and Reverse Bevel module counterbores in vertical orientation, and reverse bevels in angled orientation. The LDSF Large Diameter Split Frame takes corrosion protection to a new level with virtually every surface treated. Its attractive red powder coated finish proudly reflects E.H. Wachs corporate colors.

DynaPrep LDSF Applications

E.H. Wachs DynaPrep LDSF split frame clamshell machine tools are the foundation of a complete large diameter pipe machining system that performs a wide range of fabrication and field machining applications. DynaPrep LDSF weld prep machine tools can perform precision inline pipe cutting, squaring of pipe ends, plus flange facing of large flanges and in situ machining of vessels, heat exchangers and steam generators.

A pipe cutter by definition, the DynaPrep LDSF pipe cutting machine can simultaneously cut and bevel inline pipe, vessels, heat exchangers and steam generators. Standard equipment includes out-of-round OD tracking tool slides, as most large diameter pipe, vessels and exchangers are seldom perfectly round. The DynaPrep LDSF can quickly prep thin wall or out of round piping with its standard tool slides. For machining of heavy wall pipe, vessels or high alloy materials, additional modules are available that mount without modification to the standard LDSF ring set.

Modules and kits broaden the applications of the DynaPrep LDSF. Pivot slide and Profile slide kits allow for counterboring and deep counterboring, plus single point machining of advanced weld prep profiles and heavy wall machining up to 6in (152mm). A form tool adapter kit is available for form tooling, where the form tooling has the final weld prep profile built in.

The Profile slide kit is multi-purpose, used to bevel heavy wall pipe, vessels, heat exchangers and steam generators, plus face large diameter flanges. Onsite, after pipe cutting and counterboring the DynaPrep LDSF can double as a flange resurfacing machine, performing bolt face resurfacing, raised face resurfacing, and record grooving on very large diameter flanges, often eliminating the need for a large dedicated OD flange machine.

-

DynaPrep LDSF 75 Large Diameter Split Frame Clamshell Pipe Cutter/Beveler

Read more -

DynaPrep LDSF 90 Large Diameter Split Frame Clamshell Pipe Cutter/Beveler

Read more -

DynaPrep LDSF 105 Large Diameter Split Frame Clamshell Pipe Cutter/Beveler

Read more -

DynaPrep LDSF 120 Large Diameter Split Frame Clamshell Pipe Cutter/Beveler

Read more