Unlocking the secrets of safe, portable pipe cutting.

In the past, traditional pipe cutting was a labour-intensive and hazardous process for the personnel involved, often exposing them to potentially fatal or life-changing injuries.

Modern pipe-cutting machines and techniques have transformed the industry, and the equipment available today is a direct outcome of ongoing improvements catering to the needs of the industry.

Not only have these advances lead to better-quality products, but they have also resulted in improved safety measures, increased efficiency and cost-effectiveness, greater reliability, and enhanced design for easier handling.

Safety Benefits

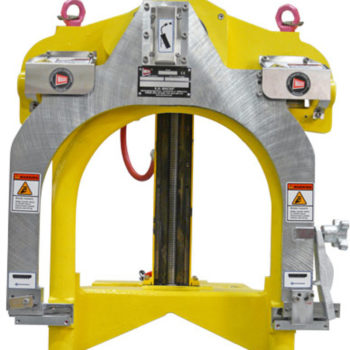

Valvemax and EH Wach’s highest priority is safety, and the Diamond Wire Saws are designed to eliminate common hazards involved in pipe cutting. The saws strap securely onto the pipe eliminating the danger of kickback accidents while the Pinch Proof Technology along with the guillotine style design prevents any offline cuts and blade jams.

A motorized wire blade means no unnecessary force is added, decreasing the possibility of blade fragments flying off and potentially harming the operator or a bystander. Quick and easy operation no longer requires workers to endure long hours of heavy-duty physical labour and exposure to harmful fumes and dust, minimizing operators’ fatigue.

Quicker and Easier

Valvemax Pipe Cutting Tools and Equipment are simple and easy machines to set up and operate, reducing your setup and cutting time, allowing operators to get jobs done faster, freeing up their time and further reducing any delays.

With the ability to mount vertically or horizontally, Wachs pipe cutters can tackle any job with ease. Capable of cutting all types of pipe materials, including stainless steel, acid-proof steel, and cast iron. During operation, debris is efficiently cleared, and the feed pressure indicator displays stress levels on the wire – allowing the operator to monitor the progress.

With handgrips for 2-person mounting, the lightweight durable operation can be safely completed by 1 handler. Wachs pipe cutters can be directly connected to Wachs TM-7 or a standard HPU, saving you time and minimizing bottlenecks in your operations, and are equipped with user-replaceable clamp contact pads and wheel inserts to make maintenance a breeze.

Cost Efficient

Wachs pipe-cutting tools are designed to be compact – requiring less space to operate and store than traditional pipe-cutting methods. This allows work to be easily completed in more confined spaces.

This allows you to spend less time and resources on preparation, as it is no longer necessary for workspaces such as pits and trenches to be as wide or deep. Achieving better cost efficiency by conserving time, money, and materials through quick and precise cuts, minimal heat generation, and lower oxidation in metals like stainless steel.

Modern pipe cutting provides consistently smooth and precise cuts reducing material waste while the load-sensing features preserve the wire life.

Most importantly – modern pipe cutting equipment reduces safety incidents, saving the user and bringing many safety benefits to the organisation.

Lightweight, Compact & Portable

Lightweight and sturdy, with the added convenience of being able to fold down for transport and for quick easy storage.

Eliminating operator fatigue caused by manual handling of heavy hand tools used in traditional pipe cutting that was detrimental to the workers’ health. As a result, workers can achieve greater efficiency and ergonomics with these saws, making them an invaluable tool for those who require a more advanced solution.

Valvemax, along with our range of Wachs tools, focuses on delivering secure and effective solutions for your business needs to protect your staff, increase productivity, and propel your business forward. Enhancing efficiency while ensuring the safety of your employees from strenuous physical work, we offer compact and user-friendly options that can help simplify your workload and take your business to new heights.

-

Wachs Diamond Wire Guillotine Saw 208

Read more -

Wachs Diamond Wire Guillotine Saw 416

Read more -

Guillotine Saw Super C

Read more -

Guillotine Saw Model D

Read more -

Guillotine Saw Super D

Read more -

DynaPrep SDSF Small Diameter Split Frame Clamshell Pipe Cutter/Beveler 4.0

Read more -

DynaPrep MDSF 6672 Split Frame Clamshell Pipe Cutter/Beveler

Read more -

DynaPrep LDSF 105 Large Diameter Split Frame Clamshell Pipe Cutter/Beveler

Read more

—

Valvemax are the industry-trusted provider for valve maintenance and repairs. With years of specialised experience and a highly regarded track record in rehabilitating valves, we can help you avoid costly replacements. After repair, Valvemax can work with you to implement a routine valve maintenance program, to help reduce ongoing costs and ensure no interruptions to service. This includes locating and exercising valves. With a range of service levels to fit your needs, speak to a Valvemax expert today and see how you can save and avoid costly replacements.